If time is of an issue for you as a reader, Project Neymar is also cleverly represented in only a few seconds long video. This video was successful at the UT's '20 seconds science' video competition, where it won the Jury Award. On top of that, the very same video also became the winner of the competition at the EuroNanoForum 2015 conference, taking place in June 2015 in Riga.

Collaboration

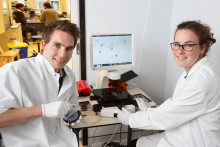

Project Neymar is a research project partly funded by Noreyk b.v., a company from Enschede, and it involves a collaboration between the Complex Tissue Regeneration Department of the MERLN institute (Maastricht University) and the BIOS Lab-on-a-Chip group at the MESA+ Institute for Nanotechnology. However, the main research is conducted at the University of Twente by Martijn Tibbe and Anne Leferink with the help of two UT students.

New type of bone cement

‘The main goal of the research is to repair bone defects’, clarifies Tibbe. ‘Nowadays, bone cement is used, but there are issues associated with it. We aim to improve currently applied methods by using engineered micro-objects that are completely biocompatible and biodegradable. We combine these micro-objects with stem cells, by which we essentially create a new type of injectable bone cement that is able to form into an ideal shape and - once injected - is more mechanically stable.’ If successful, the materials could be used to treat, for example, complex bone fractures or fractures caused by osteoporosis.

Product for clinical practice

While Anne Leferink is in charge of the in vitro characterization of the micro-objects and the project as a whole, Martijn Tibbe is focusing on different production methods. ‘Now we are trying to really develop a product to apply in clinical practice. We are aiming to improve the production speed of the materials and we are looking into methods to improve their injectability’, says Tibbe. ‘Within a year, we should be able to see if all of that is possible.’