In a newly funded OTP NOW project, Stamatialis collaborates with Utrecht University (Roos Masereeuw), Maastricht University (Aurelie Carlier) and UMC Utrecht (Karin Gerritsen) to optimise and validate an upscaled bio-artificial kidney.

Quite high mortality

In The Netherlands, thousands of kidney patients require weekly dialysis. During this treatment, the patient’s blood is filtered through membranes, that remove toxic waste products, like urea and creatinine, resulting from the body’s metabolism. ‘Typically, a patient needs dialysis therapy three times per week for four hours at the hospital’, Stamatialis says. ‘The therapy keeps patients alive, until a kidney transplant is available but it is far from perfect. The patient mortality is quite high, and their quality of life is low’.

This is due to limited removal of toxins, less than ten percent of toxins is removed in comparison to a healthy kidney. Especially the larger toxins and those bound to protein are hardly removed. ‘Besides, the patient is in a constant state of inflammation’, Stamatialis says. ‘This makes them really vulnerable to other infections, like COVID and heart diseases.’

‘Dialysis is an expensive therapy, costing about 100,000 euros per patient per year’

Besides toxic waste products, dialysis also removes valuable molecules, like calcium and potassium. And since a sick kidney cannot produce sufficient amounts of vitamin D, hormones for regulating blood pressure, and important proteins involved in red blood cell synthesis, these patients need to obtain daily supplements to compensate. Finally, dialysis is an expensive therapy, costing about 100.000 euro per patient per year and it is not environmentally friendly since it requires around 400 liters of water and several kilograms of disposable plastics.

Several steps

In contrast to current dialysis treatments, where the blood is filtered in a single step, a healthy kidney functions by filtering the blood in several steps. The two human kidneys remove metabolic waste products by the filtration of 60 liters of blood per hour. Each kidney consists of approximately one million microscopically small filtering units, the so-called nephrons. Each nephron, in turn, contains a glomerulus and a so-called proximal tubule. Water and small molecules are mainly removed via filtration at the glomerulus, including valuable ions, like glucose, amino acids, calcium and potassium. The filtrate, resulting from the glomerulus, then enters the proximal tubule. Specialized cells in the proximal tubule walls reabsorb water and valuable components, avoiding losses of these molecules. In addition to reabsorption, the proximal tubule cells also remove larger and protein-bound toxins.

Huge improvement

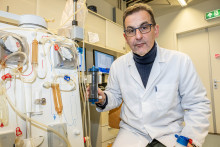

Stamatialis aims to improve kidney dialysis step by step, with an implantable device that closely mimics the function of a healthy kidney as ultimate goal. He made a first important step with improving the dialysis membranes. In the lab he shows the newest, state of the art membrane that he and his team developed. ‘This is our new M3 membrane, a new design of a blood filter, that has a higher toxin removal than the conventional dialysis filters’, he says.

(Text continues below the photo.)

He holds a 20-centimeter-long cylinder-shaped plastic chamber, a so-called dialyzer, containing hundreds of thin, black, hollow fiber membranes, less than a millimeter thick. The fiber membrane is unique: it combines filtration and adsorption. It consists of two layers: a thin, white inner part is semi-porous and filters the blood by letting toxins pass, while retaining most important compounds, like proteins. A second, black porous layer contains adsorbing carbon particles dispersed within a polymer matrix.

‘To bring this new membrane to market, we need support from investors and companies’

This membrane part improves the blood purification by adsorbing the toxins. ‘This membrane can remove quite well protein-bound toxins, that are hardly removed by conventional dialysis, this is a huge improvement’, Stamatialis says. ‘But to bring this new membrane to the market, we would need support from investors and companies, for example dialysis and polymer companies, and eventually proceed to clinical studies. We also are developing our own spin-off company to help market our M3 membrane.’

Bioartificial kidney

But the improved M3 membrane is just the first step. Stamatialis’ ambitions for improving dialysis therapy go even further. In the next step, inspired by the healthy kidney, he aims to combine the M3 filter with a so-called bioartificial kidney (BAK) device which consists of living cells from the kidney’s proximal tubule grown on polymeric hollow fiber membranes. ‘These cells are able to reabsorb water and valuable molecules, but can also remove additional toxins’, he explains. ‘If we can combine this BAK with the M3 membrane within a small unit, we may be able to deliver an implantable device that allowing the removal of more toxins 24/7. This would offer a more complete treatment and an overall better quality of life for the patient.’

Improved functionality

Since in a real kidney, there are several more filtration steps, the current BAK design is an improvement, but still quite far off from a real kidney. ‘To mimic the natural kidney function even better, more compartments with different kidney cells, having diverse functions, could be added in the future’, Stamatialis says. ‘If we want improved functionality, we need to add more different kidney cell types to a future BAK.’ To eventually provide a complete solution and reduce hospital visits and costs, scientists need to implant such a device in a patient.

Improving life of dialysis patients

To achieve this, they do not only need to mimic the natural kidney as close as possible, but also make it small enough to be implanted. If all these steps can be combined in one device, the scientists are very close to an bioartificial kidney that functions almost as a real one. It might take several decades though, before that will be achieved. But Stamatialis’ systematic and stepwise approach could gradually improved life of dialysis patients, starting with the M3 membrane.

Techmed

To upscale the M3 membranes, Stamatialis collaborates with various researchers within the Biomed 4 project, on artificial organs, of the NXTGEN HighTech growth fund program. Both M3 dialyzer development and the BAKtothefuture project are part of the TechMed strategic impulse programme KETs4PM on ‘Personalised Renal Health’ which aims to provide technological drive to transform health care and well-being.