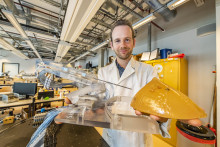

The laboratory desk of scientist Vincent Groenhuis is scattered with plastic parts, bundles of small tubes, and complicated looking control devices. But what catches the eye are the rubbery replicas of a female breast. ‘These models are used to test our biopsy robots. They are made of PVC plastisol, PVC combined with harmless plasticizers, to make it flexible and resemble breast tissue,’ Groenhuis explains. ‘We don’t use silicon, because that mutes the ultrasound, we use for guiding the biopsy needle.’

Groenhuis picks up a small, 15-centimeter-long plastic device that is somewhat reminiscent of a small armored vehicle. A long, protruding hollow needle looks like the cannon. ‘This is the latest model of my biopsy robot,’ he says. ‘It is capable of taking biopsies from breast tissue in a very accurate way.’ He places the robot in front of the breast model and with a control panel he directs the long needle with immense precision and subtlety into the rubber breast. A hissing sound from pressurized air accompanies the movement of the needle. Plastic, hollow tubes, only a few millimeters in diameter, appear to control the tiny machine. The engines inside the robot are completely made out of plastic and work on air pressure. The absence of metal parts enables the scientists to use this biopsy machine inside an MRI during the screening for possible tumors. This way, they can accurately take a biopsy of a tumor under MRI guidance.

Lethal disease

About 28 percent of all cancer diagnosed in women is breast cancer. One in seven women will suffer from this potentially lethal disease during their life time. For a successful treatment, early diagnosis is of paramount importance. After localization of the tumor, using for example MRI, the patient is transferred to another table, where a biopsy is taken manually. However, taking a biopsy accurately is tricky due to possible sudden movements and breathing of the patient.

‘As some kind of coincidence, my promotor, Professor Stramigioli, met with a company that manufactured the current biopsy systems,’ Groenhuis says. ‘They expressed their need to have a more accurate system. The ultimate goal would be to take a biopsy in ‘real time’ during the MRI scanning.’ But that also means that the robot needs to be inside the MRI machine. Since ferro-magnetic metals, cannot be used inside the MRI due to the strong magnetic field, a robot made completely out of plastic, equipped with a titanium (non-ferro-magnetic) biopsy needle, could be a solution.

Accurate biopsies

Groenhuis started his research to develop a completely new robot system, able to take accurate biopsies. His first design was inspired by other researchers and was a rather large, 3-D printed plastic robot. ‘The advantage of using 3-D printed parts is that after the design is ready, it can be printed and subsequently assembled rather quickly,’ Groenhuis explains. ‘In a short time, you can experiment a lot with different designs.’

During his research, the design of his robots became more and more sophisticated. The first prototype was as large as 30 centimeters and had seven pressured-air driven motors. Groenhuis managed to let his robots evolve to smaller and better performing designs. A few models later, a tiny robot came to life. Its size was roughly a third of the first prototype, thanks to smaller motors and a better integration of these motors into the design. Also, the performance of the motors was much better, with a higher precision to move the biopsy needle. This prototype, called the Stormram 3, was small enough to fit into an MRI, allowing to take real-time biopsies, during the MRI scan. Groenhuis: ‘This results in a quicker and more accurate diagnosis, while minimizing discomfort to the patient.’

With his different robot designs, Groenhuis won three times a prestigious prize during the Surgical Robotic Challenge in 2017, 2018 and 2019 on the international Hamlyn Symposium in London. The latest version of his robot, Sunram 5, has some major design improvements compared to the latest Stormram design. Groenhuis: ‘We use in total 6 motors, of which two are so-called dual-speed motors. These motors combine a higher speed with an even better accuracy.’ One motor is used to bridge relatively large distances, while the other motor is used for fine-tuning. In addition, the biopsy system is integrated into the robot, making it easier to take biopsies during the MRI.

Different philosophy

Parallel to designing the Stormram and Sunram robots, Groenhuis is also participating in an EU project (MURAB) aiming at improved efficiency and accuracy of taking biopsies during cancer screening. As part of this project, Groenhuis is developing a completely new biopsy robot design. The screening combines different technologies. First, an MRI scan is taken from the breast tissue. In another room, an ultrasound is taken by a multifunctional robot and software combining the MRI and ultrasound images for accurate location of the potential tumor guides the biopsy robot in real time. The biopsy robot exactly places a hollow, so-called, needle guide on the breast. Then the radiologist takes a biopsy through the needle guide. This workflow combines the MRI’s high precision with the benefits of real-time ultrasound guidance during biopsy. ‘My Stormram and Sunram robot designs have a different philosophy regarding taking biopsies than MURAB,’ Groenhuis says. ‘But I think both have a large potential.’

The MURAB project will end this year, but Groenhuis is not done with his research at all. Currently, he is working on several different projects at University of Twente. One is MultiMotor, a project which aims to develop a motor with multiple independent output shafts in order to activate robots and other complex devices with a single unit. ‘I still have so many ideas,’ he says enthusiastically. ‘My work is by far not over here!’