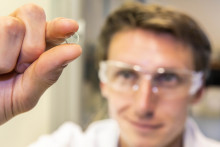

Materials science is a field full of surprises and discoveries, as UT scientist Piet Driest found out during his PhD research. He applied the chemistry of strong polymer coatings and paints to polyethylene glycol (PEG), a biomedical polymer used in for example burn patches, skin cream and lubricants. The modified PEG is mechanically strong, contains a lot of water and doesn’t interact with biological substances like proteins. This makes it suitable as contact lens material. Other medical applications are possible as well, for example artificial cartilage.

Driest started out to study the chemical characteristics of polyurethane isocyanurate (PUI) materials, a type of polymer used for coatings in the shipping and car industry. ‘This type of polymer is commonly used as a coating or paint’, Driest explains. ‘It is very strong because the isocyanurate groups bind individual polymers together to form a strong network structure. They are linked in such a way that this network resembles chicken wire.’ Driest thought out-of-the-box and came up with a plan to apply the network structure to other polymers, more specifically, to biomedical polymers, with the intent to make them stronger and tougher, while maintaining their essential biomedical qualities. If this would succeed, a different compound with more medical applications could be the result.

Lacks strength

As a starting point for applying the PUI network structure to other polymers, Driest studied polyethylene glycol (PEG), a polymer commonly used in cosmetic products as well as biomedical applications, like burn patches designed to relieve and cool burns. This hydrophilic, gel-like substance potentially has many more uses as a biomedical material, due to its inertness: it hardly reacts with other biological components in the body. However, the gel-like consistency of PEG lacks strength for wider applications, and therefore its use is rather limited. ’By giving this material more strength, it could be applied to many more biomedical purposes’, Driest says. ‘Therefore, I investigated the possibilities to apply the strong network structure to increase the strength of PEG polymers.’

Best of two worlds

Driest developed a fundamental chemical approach to improve and strengthen the existing PEG polymer-based biomedical materials. By chemically knotting the ends of the individual polymer molecules together, they would form a network structure, similar to that in existing polymer coatings. ‘As a first step, we coupled isocyanates to the ends of the PEG polymers’, Driest explains. ‘Next, by a chemical reaction called ‘trimerization’, isocyanurate groups are formed which knot the polymer ends together in groups of three. Eventually, this resulted in a network structure similar to the polymers used in coatings and paints.’ By combining the excellent medical properties of the PEG polymer with the strength of the network structure, the scientists managed to combine the best of two worlds. Driest’s basic scientific research resulted in a new polymer with unique qualities: strong, tough, transparent, biologically inert and containing a lot of water as a bonus. Owing to these characteristics, the new polymer has many potential biomedical uses. Driest: ‘We managed to increase the strength of a known biomedical substance, and I expect that there are many other uses in medicine that this material can be used for.’ In addition, similar to paint coatings, it showed excellent optical properties as well, making it suitable for even more diverse applications.

Unique set of properties

Having developed a completely new, strong and tough biomedical material, the scientist wondered where it could be applied to work best. Because of the unique set of qualities, combining excellent optics, biological inertness, high water content and strength, he imagined it might be suitable for use in contact lenses. Driest: ‘The contact lens industry is definitely interested, since there is a clear need for better contact lenses.’ Traditional so-called ‘soft’ contact lenses are not strong enough: they easily tear. The ‘hard’ lenses are strong, but, like the soft lenses, lack enough biological inertness: proteins and other biological components from tear fluid stick to these lenses over time, blurring them.

Surprising result

The application of the chemistry of industrial coatings to biomedical compounds, resulting in a widely applicable new biomedical material, is a surprising result. Driest: ‘Beautiful and unexpected things happen at the interface of different disciplines.’ Application in contact lenses is just one of the possibilities. Although the new material is currently not sufficiently resilient for application in more heavy-duty use, the scientist also sees uses as load bearing material in the body in the future, for example as artificial cartilage. It is quite a challenge though to keep the material’s toughness, while also preserving the high water content, essential to maintain its biomedical properties. Future research could solve this issue, for example by mixing the PEG polymers with other types of biomedical polymers and chemically linking them together. This could result in one strong network with a set of properties optimized for the specific application in mind, in this case, a high water content combined with high strength. ‘We delivered the proof of principle’, Driest says. ‘The next step is to fine tune and extend the concept to improve the strength of these materials even further and make them suitable for different applications. A lot is possible!’